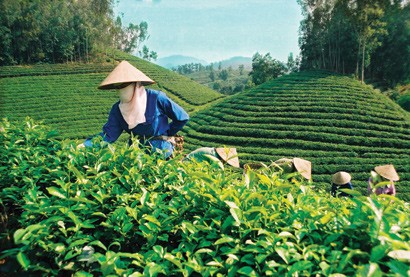

Vietnam has many favourable conditions for agriculture development, in which tea is one of the products with significant advantages. But for a long time, the Vietnamese tea industry has not had a good structure and clear, consistent strategies. How to improve the quality and sustainability of the tea industry is the main content of the conference recently held by the Ministry of Agriculture and Rural Development (MARD), Unilever Vietnam and some international consulting organisations in Hanoi.

High quality tea not in a focus

According to statistics of the Department of Crop Production (MARD), in 2013, the country’s tea area was 135,300 hectares, of which tea used as raw material for processing was 128,200 hectares, fresh tea 7,200 hectares. Fresh tea yield reached 79.5 quintals / ha, equivalent to 2012. Bud tea production reached 909,700 tonnes, export value reached US$222 million. In the first 3 months of 2014, Vietnam exported 24,000 tonnes of tea, earning US$37 million. The Department of Crop Production also announced that in period 2005-2013, 12 new tea varieties have been recognised for production, including LDP1, pH8, PH9, PH10, PH11, PH12, Phuc Van Tuyen and Kim Tuyen.

Advanced farming techniques are currently being applied nationwide, such as erosion control, reasonable planting and mechanised tea picking (6,000 machines).

Despite favourable weather conditions and having high tea planting and harvesting output compared to the world, Vietnam tea has not established itself under global quality standards to elevate export value. Therefore, at this conference, Unilever reported operations of the project "Mainstreaming smallholder farmers into high-quality and sustainable tea supply chain in Vietnam" deployed from January, 2014. Accordingly, the project is aimed to increase production of Rainforest Alliance certified tea in Vietnam; to improve sustainability in terms of economy, environment and society of small-scale tea households and tea factory owners in Vietnam. The project has the participation of provinces such as Phu Tho, Tuyen Quang, Lam Dong, Yen Bai, Vinh Phuc, Nghe An and 30 tea factories and 20,000 households, with the budget of EU£440,000.

However, Mr Flavio Corsin, an agricultural expert, Director of IDH Vietnam said there are many inadequacies in Vietnam's strategic development direction for the tea sector. In particular, the tea industry structure in central and provincial levels is limited; there is no consensus between public sector and private sector in improving the quality and sustainability of the tea industry. Besides, the production efficiency in plants remains low; management boards of a number of plants are not really interested in tea production certification; some tea companies want to produce in accordance with the State’s standards but funds are still limited. Currently, many factories which have low production efficiency based on standards issued by the state, plants type C (do not reach requirements), type B (medium) are allowed for tea production.

Another problem is that management boards of some factories do not pay enough attention to certified tea production because the uncertified tea market accounts for a large proportion of their business. Some tea companies want to apply the State’s standards, but they do not have enough capital to invest in equipment. Besides, the number of factories investing in material areas made up for 35.5 percent; the number of factories applying ISO and HACCP standards was16 percent. Therefore, the main tea product structure focuses on black tea OTD, CTC, but not green tea, oolong tea or high quality tea products. Enterprises have not built the tea brand, leading to low export tea price and limited added value.

Solutions for quality

According to Mr Cao Duc Phat, Minister of Agriculture and Rural Development, today's tea production of Vietnam is not commensurate with the potential; moreover, the tea export price in Vietnam is very low. Objectives in the medium and long term are to increase tea production for export in Vietnam through helping tea farmers and selected tea factories to achieve a minimum of 4.0 in the quality index.

Currently, Vietnam’s export tea reached only 3.6 of quality index, so, to achieve 4.0, Vietnam needs to implement measures such as establishing a tea industry coordination committee based on the coffee coordination committee, with the participation of relevant ministries (Ministry of Planning and Investment, Ministry of Agriculture and Rural Development, Ministry of Industry and Trade) and provincial agencies (local representatives with large area of tea production). Besides, tea factories type B or C should be alerted and trained to gradually improve the effectiveness ịn accordance with State standards. Within 6 months (for type C) and 3 years (for type B) after being warned, if tea factories cannot upgrade, they will be suspended; need to accelerate the certification for tea factories. At the same time, VN also needs to develop incentives to stimulate certified factories (not just VietGAP). The incentives may include technical support, improving capital access, and lower taxes. Through existing farming channels, the Government should disseminate the sustainable tea production to the whole community.

Mr Nguyen Huu Tai, Chairman of the Vietnam Tea Association, said that one of the underlying causes for the decline of tea quality as well as competitive export value of Vietnam's tea industry is due to breaking down value chain link in tea production for a long time, especially after 2005. Besides, the waste in manufacturing processes at the tea plants also causes the reduction of tea production efficiency. Thus, the radical solution in the near future is having a balanced strategy of material areas providing for plants and there needs to be legal manufacturing contracts among farmers and collecting plants.

Source: Vietnam Business Forum